安全生产 警钟长鸣

发布时间:2023-08-23

安全生产 人人有责

“安全生产”,是指在生产经营活动中,为了避免造成人员伤害和财产损失的事故而采取相应的事故预防和控制措施,使生产过程在符合规定的条件下进行,以保证从业人员的人身安全与健康,设备和设施免受损坏,环境免遭破坏,保证生产经营活动得以顺利进行的相关活动。

01 安全生产以预防为准

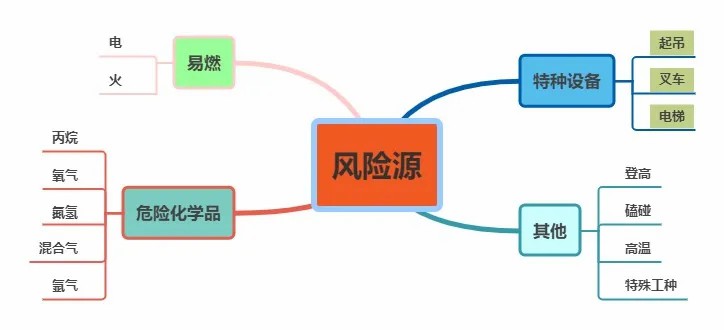

主要安全风险源

02 针对主要风险源做相应预防工作

1 用电安全

执行电气安装和测试的人员需要持有上岗证才能上岗;

车间人员严禁私拉乱接用电设施,严格按照用电使用规范进行操作;

安装、使用带电设备的人员需要穿绝缘鞋在在干燥的空间操作,严禁带电操作;

定期线路是否有破损;

2 用火安全

从事焊接作业的岗位周边5米以内不能有易燃、易爆的物品;

车间人员除工作必须使用明火外,严禁私自使用明火;

从事焊工作业的人员需要持证上岗且上岗证在有效期内;

从事动火的人员需要有动火名单登记;

关注安全 珍爱生命

3 用气安全

运输:丙烷与氧气不能同时运输、气瓶在运输过程中需要固定牢靠,防止碰撞,要轻拿轻放;

使用:丙烷与氧气间隔距离应超过5米,离动火点需大 于10米,需要有牢固的固定,点火时,先开丙烷,后开氧气,关火时,也是先关丙烷再关氧气;

每天上班前检查气体管路有无泄漏;

气瓶储存:空瓶与满瓶要分开放置,需要固定后立体堆放,氧气与丙烷不能放置在同一个房间内储存;

4 特种设备使用安全

行吊使用前:起吊人员必须配戴安全帽、明确载重量是否在行吊承载范围内,检查起吊设备是否有完好,钢丝绳、安全带是否有损伤。起吊时要缓慢移动,严禁在起吊设备下面站人。起吊大型设备时、必须有2个及以上的人员在现场;

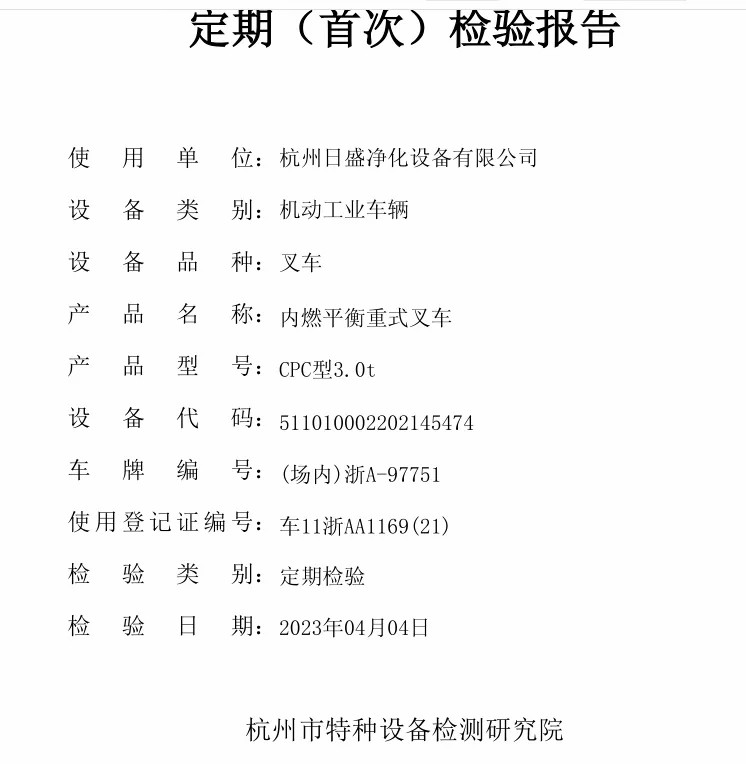

使用叉车的人员必须持证上岗,且上岗证在有效期内,使用叉车前需要对叉车的性能进行检查,确认完好后方可使用,严禁叉超过自身载重的货物,行驶时,货叉底端距地面高度应保持300-400mm,停放时货叉需要落地定点停放;

非拉货人员禁止乘坐电梯,严禁拉超出电梯载重范围外的货物进入电梯,严禁带易燃易爆物品进入电梯,物品乘电梯时要放在电梯中间位置,严禁碰撞电梯,和强行打开电梯;

特种设备在特检网站报检提交,行吊和叉车每两年报检一次,电梯每年报检一次,预约好时间后,特检院会派人来公司对报检设备进行检测,合格后发检验报告和使用标志;

5 登高与防磕碰安全

从事超过2米高度的高空作业人员需要持证上岗且上岗证在有效期内;

从事高空作业人员需要佩戴安全带或者是安全绳、佩戴安全帽;

在机械制造车间的人员需要穿防砸的劳保鞋;

6 高温作业安全

车间降温:冰块、风扇等;

防中暑药品;

7 特种作业人员安全

防护用品如:安全带、安全绳、安全帽、绝缘鞋、防护罩、护目镜、口罩、耳塞等;

车间设置有医药箱配备:跌打损伤、烫伤类的喷剂、药物和感冒药等;

03 培训

安全培训

公司每年不低于两次外请专业机构人员给员工做安全消防演练;

安环办会不定期的给员工做安全生产的培训;

车间晨会给员工灌输安全意识和安全注意事项;

04 制定安全规章制度

规章制度

针对不同的工种制定不同的规章制度;

对违反安全制度的人员进行警告、劝阻和处罚措施;

只有强化安全意识,增强责任心,生命财产才不受威胁, 安全才有保障,安全生产才有可能实现。因此,我们日盛工业把安全牢记在心中,是我们必须坚守的神圣职责。把安全印在心中,时刻绷紧安全这根弦,让安全生产、安全工作切实落实到实处,从身边的小事抓起,消除一切可能发生危险的隐患,让我们的生产和各项工作都处于一个安全的环境之中。

团结 | 合作 | 共进

- END